Activity Overview

The Laboratory of Testing Materials and Structures (LPMS) run for the benefit of private and public administrations, standard tests and complex. The former includes the compression tests on cylindrical and cubic samples, possibly shortening to measure the concrete core sample; Tensile tests to failure of reinforcing bars (lengths longer than 500 mm) or on steel samples, possibly taken from rolled profiles and machined to the cutter inside the workshop. For the samples can be applied an extensometer to measure the deformation to 0.2%. Requests for information and evidence must be sent to the email address lpms.standard@unitn.it

The complex tests include tests, light and heavy, requiring additional instrumentation such as external displacement transducers, strain gauges, load cells, electro-hydraulic actuators or jacks hand; or those that require load cycles complex or high speed or frequency.

Without limitation, the complex tests frequently performed by LPMS:

-

- Tests on wood and its derivatives: resistance to bending, compression, shear and transverse plane, both on small sample size in structural dimensions. Such tests have been carried out on multilayer boards, composite slabs of wood – concrete trusses of very light on structural panels for houses in wood, wood panels with different types of constraints.

- Tests on concrete: bending tests and of elastic modulus.

- Tests on stainless steel elements or compounds – cls: pipes of large diameter, high-strength threaded rods, knots beam – column.

- Load tests on floors or structures: the acceptance tests on bridges, pedestrian walkways, floors.

- Non-destructive testing: sonic tests and with flat jacks on masonry; extraction tests of bars glued; pull-out tests; evidence Resistograph and pilodyn.

- Vibrational tests: tests on external structures, such as bridges or buildings, and laboratory tests such as wind turbines or prototypes of the slab.

- Fatigue tests on elements in actual size.

The feasibility of testing complex outside standard is assessed on the basis of the needs of the applicant and of the allocation of LPMS: retaining elements can be designed by dedicated LPMS and that it can deal directly with the execution. Requests for information and evidence must be sent to the email address lpms.complex@unitn.it

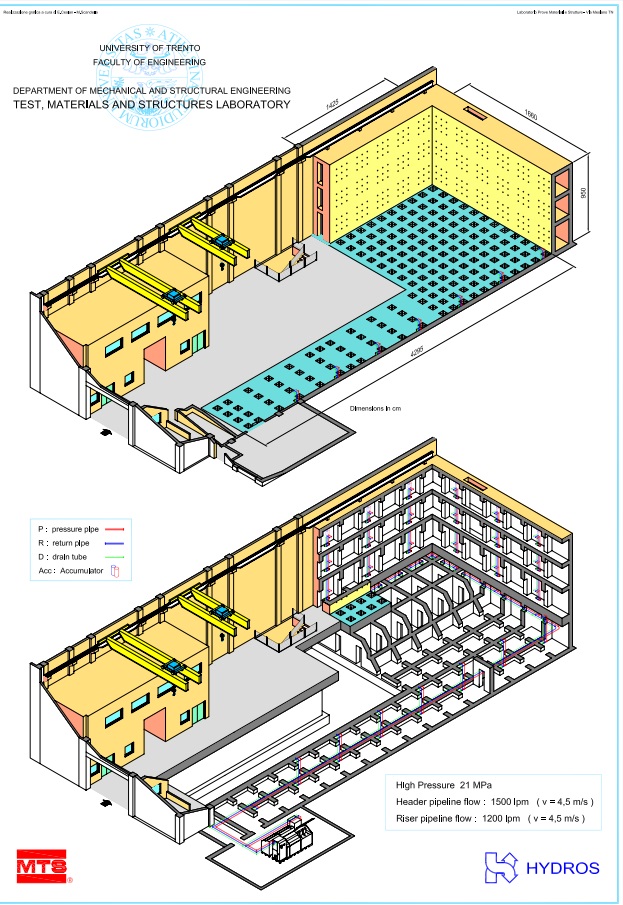

Structure of the reaction (see 3D sketch)

The hydraulic system of the new Large-Scale Testing Laboratory (dimension 4295 x 1660 x 950 cm) has been completed in fall 2002 (see detailed document). It has the following general characteristics:

-

-

- Header pipeline flow: 1500 lpm (v = 4.5 m/s);

- Riser pipeline flow: 1200 lpm (v = 4.5 m/s);

- Engaged power of 600 kW;

- Work (high) pressure of 21 MPa.

-

The following equipment is available in the laboratory:

-

-

- Oleodynamic universal testing machine – Metrocom – 1000 kN;

- Mechanical universal testing machine – Galdabini – 100 kN;

- Compression test rig – Controls – 300 tons;

- +1000/-1000 kN MTS dynamic actuator;

- +1000/-640 kN MTS actuator;

- Jacks and reaction frames up to 2000 kN.

-